Structure of a single screw compressor Download Scientific Diagram

A screw compressor works by having two rotating parts that draw air in between them because they move in opposite directions. As the air moves through the rotors, it compresses the space between them, resulting in compressed air. This process generates compressed air and pushes it our through the outlet. The rotors are set an ideal speed to.

Rotary screw air compressor Extraction Future4200

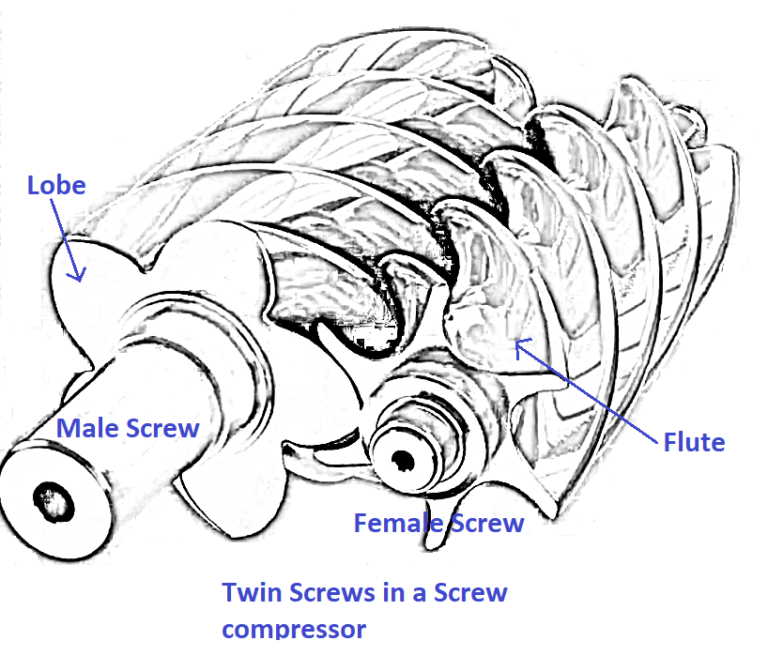

Figure 1: Twin screw compressor With the rotation, the leading strip of the male lobe reaches the contour of the female groove and traps the air in the pocket previously formed. The air is moved down the female rotor groove and is compressed as the volume is reduced.

Cross Section Of Rotary Compressor

Screw Compressor animation | Howden Howden 8.57K subscribers Subscribe Subscribed 2.6K Share 334K views 6 years ago Howden manufactures oil injected and oil free rotary twin screw.

Rotary Screw Air Compressor Diagram lupon.gov.ph

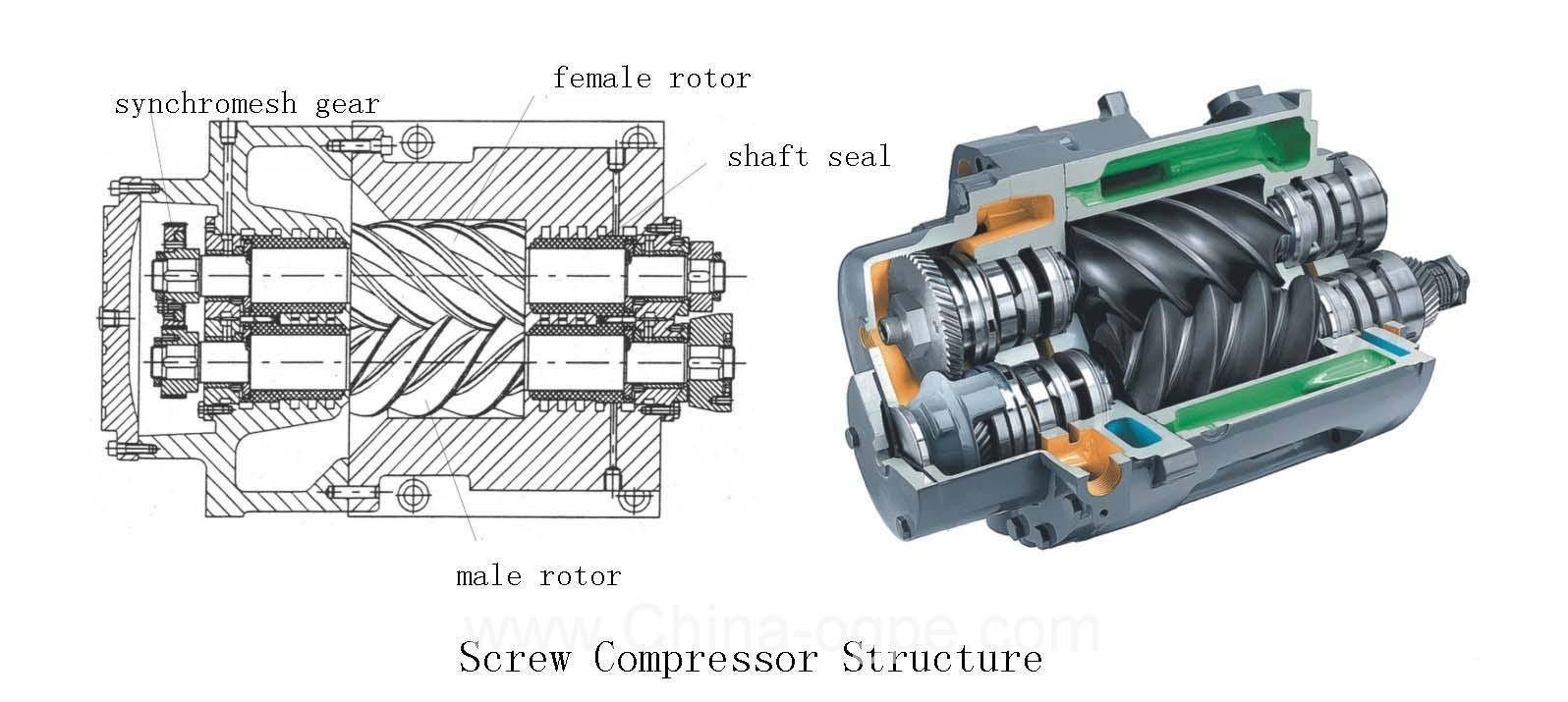

A screw compressor is a type of positive displacement compressor that uses two spiral screws to compress the gas. It uses a positive displacement rotary mechanism for the compression of gas. The screw compressor has two below given meshing spiral screws (called rotors) for the compression process: Male rotor Female rotor

Schematic drawing of the compressor test system. Schematic drawing of... Download Scientific

Context 1. a thermodynamic point of view, the screw compressor is considered to be an open system because, during the operation, during the working process, a mass change with the external.

Screw Compressor MechanicsTips

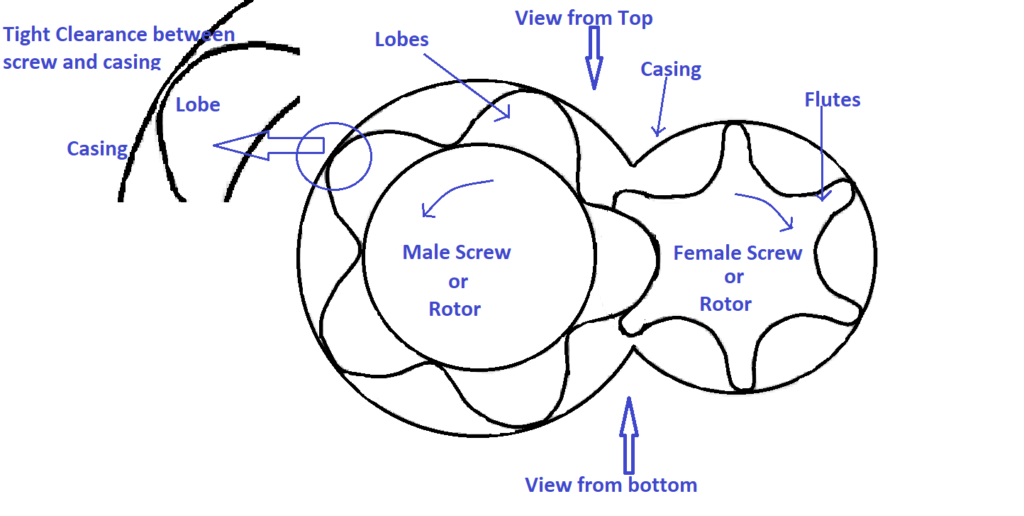

Rotary screw air compressors use positive displacement, a process that involves pulling air into a chamber. It reduces the volume in the chamber to compress the air. Rotary screw air compressors, specifically, utilize positive displacement with spiral screws that rotate in precise alignment.

ELGi's Australia reliable and ease of maintenance screw air compressors designed to reduce

Rotary Twin Screw Compressors for industrial refrigeration, gas processing and other industries. Rotary twin screw compressor technology was developed in the 1930s by a Swedish company, SRM, in collaboration with Howden. We manufactured the world's first operational screw compressor and further developed the technology in the 1960s with the.

How Air Compressors Work An Animated Guide BigRentz

The working principle of a screw compressorscrew air compressor working principleFirst of all, let us take a look at the rotary screw compressor element. The.

Oil injected screw compressor [4] Download Scientific Diagram

Figure 1. Horizontal Section of Dry Screw Compressor with Main Components. Rotor Profile Considerations The lobe profile and the number of lobes on the male and female rotor may differ for different machines.

Centrifugal Air Compressor vs Rotary Screw Few merits and demerits

Rotors /Rollers Rotors or rollers are the heart of the rotary screw compressor. They come in pairs and are inside the cylinders of the compressor. Rotors rotate at high, sweeping speeds creating a pipeline for suctioned air to move through, compress, and discharge out of the system. Compression Cylinders

Patent US6450771 System and method for controlling rotary screw compressors Google Patents

A rotary screw compressor's defining characteristic is the presence of screws (usually there are two, but the compressor may have more or less). These are also called the male and female rotor elements, and they are driven either by the male rotor or by a timing gear.

Diagram of rotary screw compressor 1 compressor suction area, 2 screw... Download Scientific

Screw compressor is displacement compressor, in which, compression of vapour refrigerant is accomplished by two mutually engaged helical grooved rotors enclosed in a casing. The rotor, whose shaft is connected to the motor, is called as male rotor (driving rotor) and the other rotor is called as female rotor (driven rotor).

Screw Compressor Working Principle The Mechanical Engineer

screw compressor diagram The working cycle of the screw compressor has three distinct phases as following: (i) Suction process (ii) Compression process (iii) Discharge process (i) Suction process: As the rotors rotate, air is drawn through the inlet opening to fill the space between the male lobe and the female flute.

Screw Compressor Working Principle The Mechanical Engineer

A rotary screw compressor draws air in. The air first travels through a filter, then through an open inlet valve into the compressor element. This inlet valve is effectively a one-way valve. When the compressor is turned off, the valve closes, stopping air and oil from heading into the filter. The air is compressed in the compressor element as.

25+ Best Looking For Semi Hermetic Compressor Line Diagram Ralf Hirsch

Rotary Screw Compressor: Definition, Types, Working, Diagram, Application, Advantages & Disadvantages :- A screw compressor is a type of rotary compressor that uses the screw motion to compress fluids, generally air. The key benefit of employing this compressor is that it can constantly compress air with little variation in delivery pressure.

Gas Compressor Types, Sizes and Functions by Helmi Wicaksono Muchammad Medium

2. Compression chamber. Encloses the rotary screw element. It's possible to have multiple stages for more pressurization. 3. Inlet suction air filter. Set at the inlet of the compression chamber where it's possible to catch and reduce dust, and ingress of damaging particles.